Communication Facilities (Fiber Optic and Radio Frequency)

Revised July 2024

Purpose

This section is intended to identify responsibilities and risks related to the handling of fiber-optic cable and equipment.

Applicability

This section is applicable to all employees whose job duties include performing work on communication sites/facilities.

Fiber-Optic Systems

Managers must ensure all applicable employees are properly trained on the specific hazards of handling fiber-optic cable and equipment.

Under normal operating conditions, light wave transmission systems are completely enclosed. The following precautions shall be observed with these systems:

- Employees shall not disconnect any fiber-optic cable or splice and stare into the optical connectors terminating the cables because of the potential for eye damage.

- Under no circumstances should an employee who has not satisfactorily completed an approved training course perform light wave/fiber-optic operations.

- Because viewing light wave emissions directly with an optical instrument, such as an eye loupe, greatly increases the risk of eye damage, an appropriate label must appear in plain view on the front of the main frame or fiber-optic termination/interconnection equipment identifying this hazard.

During service, maintenance, or restoration work, a light wave transmission system can no longer be considered enclosed. Under such conditions, employees shall observe the following:

- Only authorized, trained employees are permitted to perform service, maintenance, and restoration work. Employees shall avoid exposing the eye to emissions from unterminated, energized fiber-optic connectors at close distances. The connectors associated with light wave regenerators are normally recessed, thereby limiting the exposure distance. Under normal conditions, the regenerators can be removed or replaced without fear of eye injury. However, employees performing the removal or replacement work shall not stare or look directly into the vacant regenerator slot with optical instruments or magnifying lenses.

- Only authorized, trained employees are permitted to use light wave test equipment during installation/servicing work, since this equipment contains semiconductor lasers.

- Unauthorized employees shall be excluded from the immediate area of light wave transmission systems during installation and service work. The area shall be properly barricaded and posted.

If a fiber-optic cable breaks or is removed from its normal position, employees should observe the following precautions:

- Do not examine or stare into broken, severed, or disconnected fiber-optic cables.

- Report any cable problems to your manager or person-in-charge, who can arrange for authorized, trained installation/service personnel to repair or replace the cables.

Employees who install, operate, maintain, or repair fiber-optic systems have, in addition to normal safety precautions, the following responsibilities:

- Observe all District rules, procedures, and practices established for the safe operation of these systems.

- Notify a manager or person-in-charge immediately of conditions or practices that may cause potential personal injury or property damage. (Stop Work Authority section of this manual)

- Report to a manager or person-in-charge immediately any known or suspected accidental exposure to laser radiation.

- Use appropriate safety glasses and gloves when working with fiber-optic systems.

- When using an ultraviolet lamp for curing adhesive during splicing of fiber-optic material, only approved eyewear shall be worn.

- Employees shall always treat every fiber as active and when using laser, take the appropriate safety precautions.

- Eating or drinking in the fiber work area is prohibited.

- Employees shall be informed not to rub eyes or use the restroom without washing their hands first.

- Do not assume that fiber-optic cable does not pose an electrical hazard. The fibers themselves are dielectric, but if the cable contains any metallic parts at all, the cable is conductive and should be treated accordingly.

- Always apply temporary grounding and bonding harnesses to the cable while working on it.

- Solvents and chemicals used for stripping fibers and cleaning shall be used in adequately ventilated areas.

Cleaved glass fibers are very sharp and can pierce the skin easily. Do not let cut pieces of fiber stick to your clothing or drop in the work area. Use tape to pick up cut pieces of the glass fibers.

Employees shall wear safety glasses and gloves when handling fibers.

When using tools such as hook blades to strip cable, employees shall guard against the blade slipping and cutting their hands and arms.

When using diagonal cutters to cut or trim the metallic strength members of the cable, do not cut more than one strand member at a time and be sure to hold the portion to be cut as close to the floor as possible away from other people.

When using razor blades for light trimming operations, always cut away from body, do not use a dull blade, do not attempt heavy cutting with a razor blade, and dispose of razor blade properly.

When using utility knives for heavier cutting operations, always cut away from the body, never use a dull blade, and hold the knife in one hand and the cable with the other.

Fiber cable sheath ease of removal is contingent on temperature. Use extra caution in colder temperatures.

Radio Frequency Radiation

Utilization of Radio Frequency (RF) Source Equipment which meets applicable safety standards:

- RF source equipment shall meet all Federal Communications Commission (FCC) RF regulations and other applicable safety standards.

- FCC certification will be required on all future purchase orders for RF amplification equipment.

- Any service, modification, or action that has been performed on equipment that is responsible for amplifying or coupling amplified signals will be checked with RF survey equipment immediately after service and before returning that system to operational status.

RF Hazard Identification and Periodic Surveillance:

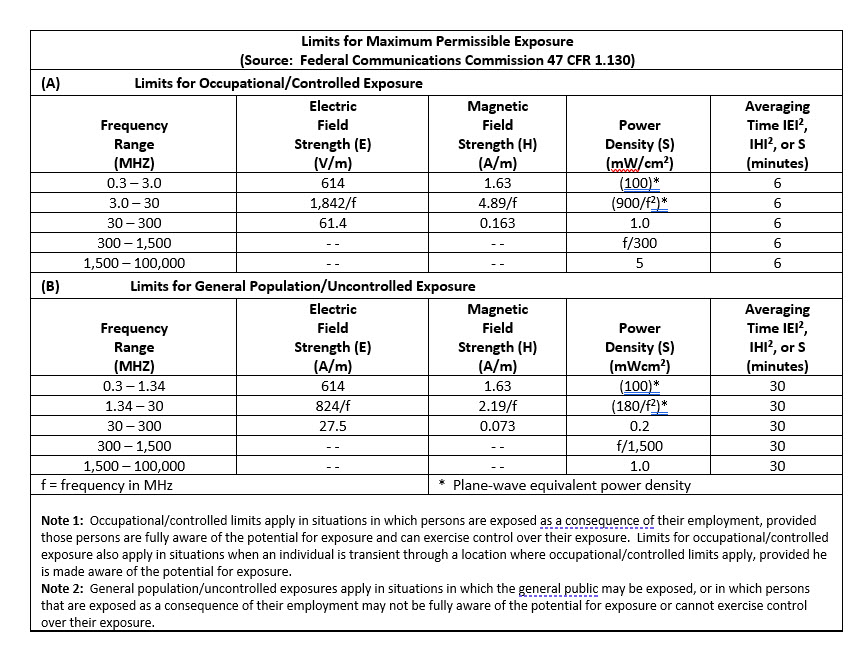

- Screening measures shall be completed to identify potentially hazardous RF areas. More complex measurements may be necessary when employee exposures approach FCC established maximum permissible exposure (MPE) limits. (See table below)

- Conducting objects in close vicinity shall be evaluated to ensure that they do not constitute RF shock and burn hazards.

- Surveys of RF levels shall be conducted during the development of work practices to ensure they are effective in preventing excessive exposures to RF radiation.

- Appropriate work practices must be followed during the repair and maintenance of RF equipment.

- Surveys of RF levels shall be conducted to ensure that personal protective equipment is applicable and effective for the specific work site conditions.

Identification and implementation of controls in RF hazard areas:

- Access to any areas where RF fields could exceed the FCC established MPE limits for the general public shall be restricted.

- Exposure time and distance between the RF source and employee shall be controlled to ensure workers’ exposure remain below recommended levels.

- RF hazard areas shall be identified to alert employees of areas that are not to be occupied during RF application.

- The antenna and transmitter shall be deactivated prior to being serviced.

- Access to RF hazard areas shall be controlled with standard lockout/tagout procedures (see LOTO section of this manual) to ensure employees are not occupying these areas during the application of RF energy.

- Transmitters shall not be operated without shields.

- Appropriately selected and properly used RF protective clothing shall be used to reduce whole body RF absorption below established MPE.

- Employees working near or in the vicinity of radiating antennas or transmitters may be required to wear and use appropriately selected personal RF monitoring devices to ensure exposure levels are below the established MPE.

- RF hazard areas shall be clearly marked with appropriate signs, barricades, floor markings, etc., such that any worker who has access to the facility will be alerted not to occupy the hazardous locations.

- Signs shall be of standard design and shape, and of sufficient size to be recognized and readable from a safe distance.

- Screening measurements shall be used to determine where signs are to be located in order to alert workers approaching a RF hazard area.

- The evacuation of hazard areas prior to RF application shall be strictly enforced.

RF Safety and Health Training & Resources

All employees who are required to work in a controlled environment, where power densities could exceed the FCC general public MPE limits, shall be aware of the potential exposure RF fields and should be informed of the steps they must take to ensure they are not exposed to RF fields in excess of the MPE limits.

RF awareness training shall include applicable principles for working safely near energized communications antennas and equipment as well as guidance for personal protection that will be encountered under specific workplace conditions.

Employees shall adhere to the following principles when working around RF equipment:

- Employees shall assume all antennas are active and energized.

- Employees shall maintain an established safe distance from all antennas.

- Employees shall obey all posted signs and warnings.

- Employees shall not stop near omnidirectional antennas or in front of directional antennas and should keep below elevated antennas.

All employees relying on and using personal monitoring equipment require training in the appropriate use and limitations of the device.

Should an occurrence of RF burn, or the sensation of non-routine heating, it must be immediately reported. (see Incident Reporting section of this manual)

Employees must notify manager or person-in-charge of any implanted medical devices prior to working around RF equipment.

Periodic RF screening and measurements are necessary to ensure conditions have not changed and District practices continue to be effective in preventing excessive RF exposure.

WAC 296-45-465 Communication facilities

WAC 296-32 Safety standards for telecommunications

WAC 296-62 General Occupational Health Standards, Part J-1-Physical Agents